There are different types of bearings. Every bearing has some fundamental design differences, such as they are differences in size usage and certain cage designs. For instance, there are some types of bearings that need either snap-type or split cages. Why? Because they are assembled after the rings and rolling elements are sub-assembled.

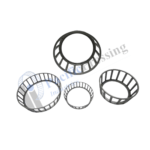

Taper Roller Bearing Cage

When it comes to tapering roller bearing cages, it is a ‘pin type’ design. According to Pacific Pressing, one of the top Taper Roller Bearing Cage Manufacturers, a pin-type cage design is perfectly fine in applications that experience very high speeds and high loads.

Main Purpose of a Bearing Cage

The role of the bearing cage (also known as separator or retainer) is to perform three main functions:

1. To space the rolling elements

2. To retain the roiling elements themselves or with one of the bearing rings

3. To guide rolling elements on their correct rolling path

Reasons Why Bearing Cage Damage

There are many causes of bearing cage failure. These reasons can be related to the mounting and handling of bearings. Problems in the cage also occur because of inadequate lubrication, vibration, heavy loads, and high temperatures. In order to prevent issues in the taper roller bearing cage, it is advisable to reduce vibration and install it as per the instruction given by the Taper Roller Bearing Cage Exporter.

Taper Bearing

Tapered roller bearing reduces friction as well as heat. Heat reduction is necessary as it can cause bearing designs to fail. The tapered shape is designed in a way to allow the transfer of a load even while rolling. This type of bearing contains both tapered raceways (inner and outer rings), and tapered rollers. The design and construction of taper roller bearings are intended for combination loads, such as radial loads and dual-acting axial. These bearings have several components, including the following:

● Cone

● Cup

● Tapered rollers

● cage (roller retainer)

In normal operating situations, all the components above (cone, cup, and rollers) are supposed to carry the load while the role of the cage separates the rollers.